We use cookies to improve our services. Read more about how we use cookies and how you can refuse them.

Metalworking Machines from Top Brands

KAMADO offers top quality industrial metalworking machines for those in the metalworking industry. Our selection of metalworking machinery includes deburring machines, cold saws, presses and more...

KAMADO offers top quality industrial metalworking machines for those in the metalworking industry.

Our selection of metalworking machinery includes deburring machines, cold saws, presses and more.

Our customers put their trust in KAMADO to supply them with whatever type of machine tool that they require because they know that KAMADO will support them after the sale and provide the technical assistance to make their processes profitable.

If you are inquiring about product information, pricing, policies or any other questions or concerns, we are happy to help in every way and look forward to hearing from you.

Our international sales department can provide metal fabrication machine solutions worldwide with international logistics and shipping expertise.

Metalworking Machines

Top quality industrial metalworking machines

Turning

Turning is one of the main types of metal cutting. Primarily intended for machining of rotation bodies (like shafts or flanges), turning is widely used for the manufacture of parts with cylindrical, conical, shaped and end surfaces with the help of cutting tools. KAMADO offers delivery of turning equipment, such as cycle-controlled CNC vertical and horizontal lathes, turning/milling centers, multi-slide automatic lathes and Swiss-type automatic lathes.

Cutting and auxiliary tools

Metalworking tools are conventionally subdivided into the cutting tools (e.g., milling cutters, drills, taps, etc.) directly used for machining (cutting), and the auxiliary tools used to fasten the cutting tools in the spindle of metalworking machine (e.g., chucks, holders, mandrels, etc.).

Tools production & sharpening equipment

Tools production and sharpening equipment significantly enhances the tools performance and failure protection and is therefore essential for every manufacturing facility.

Profile bending equipment

The professional profile bending equipment. forms the metal strip of the required shape using the rolling method.

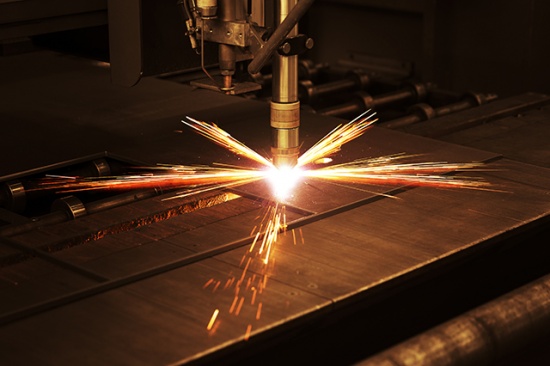

Oxy-fuel and plasma cutting equipment

Gas-plasma metal cutting is the most efficient method of sheet material processing. Plasma cutting allows to produce the parts with superbly high precision and repeatability quite fast. This method of sheet material cutting is considered to be one of the most popular in material processing. Plasma cutting is perfect for cutting of low-carbon and high-carbon steels as well as high-alloy and engineering materials.

Rolling-and-bending machines

This state-of-the-art equipment is designed for bending of metal sheets of varying thickness and length by the cold bending method (i.e. without welding or welding seams). There are several types of rolling-and-bending machines, namely, the manually, hydraulically, pneumatically, mechanically and electromechanically driven machines.

Laser machining

Laser machining is currently one of the most demanded and widely used cutting technologies in various industries. The main advantage of laser machining is its suitability for accurate material cutting with a high speed and in the shortest possible time.

Punch presses

Punch presses are designed for punching and stamping metal workpieces and punching holes of any shape as well as for shaping operations.

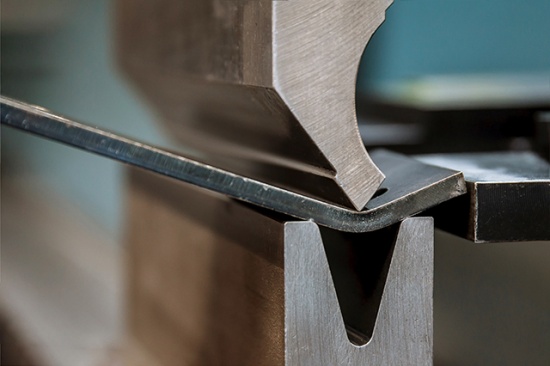

Guillotine shears

Guillotine shears belong to the kind of metalworking equipment designed for cutting and punching of rolled metal products. The material is cut (punched) by dissecting along the cutting line using movements of the top blade and the stationary bottom blade. Depending on the top blade drive type, the guillotine shears are divided into manually, electrically (electromechanically) and hydraulically driven ones.

Milling

Milling allows to produce complex-shaped parts. by means of the milling cutters that represent special tools made of special grade steel. Special horizontal and vertical milling machines and CNC milling machines are used for this type of machining nowadays.

HYDRAULIC AND MECHANICAL PRESSES

Equipment for sheet material processing by punching, forming, stamping and drawing.

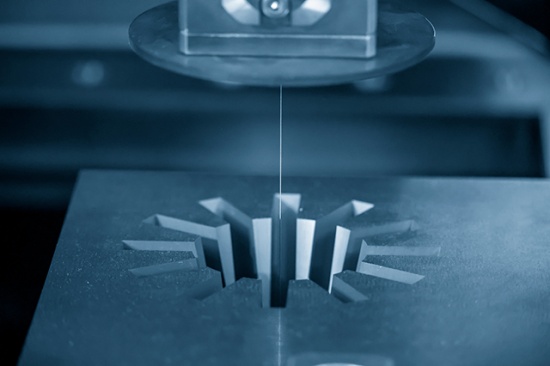

Electrical discharge machining

Electrical discharge machining allows to change the shape, size, roughness and surface properties of an electrically conductive workpiece exposed to the electrical discharges appearing between the workpiece and the tool electrode.

Heat treatment

Heat treatment equipment includes the vacuum, hardening and carburizing furnaces, etc., whose principle of operation is based on changing the structure and properties of metals as they are exposed to specific temperatures.

Drilling and thread cutting

In spite of progress in machine-tool industry, various kinds of drilling and thread cutting equipment are still popular. Both machining centers and lathes easily perform standard threading and hole drilling operations.

Tools and equipment for copper and aluminum busbars machining

Tools and equipment for machining of copper and aluminum busbars with dimensions up to 12 × 125 mm, namely: for cutting, bending and fullering as well as for punching holes in busbars and indenting steel nuts.

MEASURING EQUIPMENT

The pre-registration, measurement and tool inspection machine is crucial and fundamental for any type of workshop and metalworking industry, from automotive to aerospace, oil & gas, etc. We have a wide range of products able to satisfy your every need.